A Comprehensive Study on Garment Cutting and Quality Management Systems in the Textile Industry

The route from raw fabric to the finished wearable product involves intricate mechanisms in the continually evolving textile industry. Quality management systems and garment cutting are crucial to a textile venture’s success. We will look at the details of garment cutting and the significance of strong quality management systems in the textile sector in this comprehensive guide. In this article, we present details of A Comprehensive Study on Garment Cutting and Quality Management Systems in the Textile Industry.

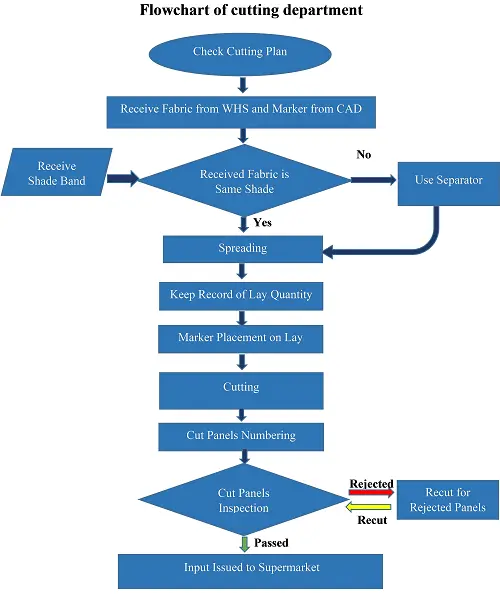

Cutting is one of the key divisions in the garments manufacturing sector, where the main operating process began. Here, the fabric is cut into pieces with the help of a marker to provide input to sewing.

Work Description of Cutting Department

The cutting department received a cut plan from PPC. As per the plan, the team received fabric from Relaxation and marker from CAD based on style, color, and PO. Cutting QA confirmed fabric shade, composition, and Fabric relaxation is ok, then start spreading and record the number of plies. During spreading QC, check the lay tension, creasing, fabric width and lay length, roll-to-roll shade variation, marker ratio, overlapping, etc. If there is no quality problem, QA is allowed to cut fabrics. If there is any roll-to-roll shade variation, a separator is used between the shading layers, and after completion of cutting, production data is stored in a record book.

After cutting, QA checks the cut accuracy by selecting panels from the cut cake’s top, middle, and bottom. After the accuracy check, goods are sent to numbering.

The numbered panels are sent to the QC table for inspection. After the inspection passed, checkers released the panels for the next process. The rejected panels are replaced with new panels with matching shade, composition, and quality after those goods are delivered to the supermarket for further processing.

Mostly used cutting equipment in garment industries

- Straight knife

- Band knife

- Computerized/Automatic cutting machine

Quality Management System

A Quality Management System, often called a QMS, is a set of internal rules that are defined by a collection of policies, processes, documented procedures, and records. This system determines how a company will achieve the creation and delivery of the products and services it provides to its customers.

Quality Management Guidelines in different stages of cutting operation

Spreading control:

- Ensure each fabric roll undergoes the relaxation system as per requirements, e.g., 12/24/48/72 hrs, before spreading.

- Before spreading, systematically check markers for length, width, panel measurements against the pattern, ratio alignment with the cut plan, pattern shrinkage, shape, and any overlaps.

- Ensure that fabric dye lot allocation aligns with the shade band, color continuity record, and shrinkage test results.

- Display the spreading speed settings for different types of fabric on the cutting floor in accordance with requirements.

- Lay the fabric flat with appropriate tension, strictly avoiding any looseness or excessive tension in fabric layers.

- Verify that the fabric height meets both customer and factory requirements.

- Place paper on the bottom of layers during spreading to prevent distortion of the fabric.

- During spreading must check fabric way, uneven shade and roll to roll shade variation among the layers.

- Develop cutting instructions specifically tailored for special fabrics, such as patterned fabric or high-elastic fabric, and adhere to them meticulously.

- After completion of spreading count all the layers from both sides to ensure consistency.

Cutting Control:

- Before cutting, check the marker and spreadsheet, and sign after confirming.

- After cutting the first cake check the shrinkage of the panels to make sure shrinkage is consistent. If not go for rectification process.

- After cutting the table QC check the cutting accuracy by taking 3 panels from the top, middle, and bottom of the cake with the pattern.

- Verify that panel dimensions meet requirements, setting internal standards such as tolerance of +1/8″ or 1/4″.

- In case of over tolerance, re-cut or change the size accordingly.

Numbering/drawing position/bundling

- Numbering: After cutting all the panels undergo a numbering system.

- NB.- If there is no issue of lot shade and uneven dyeing no need to number the panels.

- Drawing position: Check if template is correct before using, no damage, accurate position markings.

- Bundling: Panels are bundled properly with clear and correct identification/bundle card.

- NB.- In the bundling area, include a mini marker that reflects the running style to help ascertain the quantity of panels per garment to ensure accurate master bundling.

Cut Panels Inspection

- Set up a designated inspection area with proper lighting (D-65 light with minimum 1000 Lux intensity).

- There should be clear instructions in the table regarding how to check.

- There should be separate boxes to store passed and defective panels after inspection.

- Provide training on identifying various fabric defects and understanding quality standards.

- Comprehensively train checkers for confidence in demonstrating the checking system during interviews with internal and external auditors

Defective panels replacement

- After spreading, the leftover fabric from each roll is collected and clearly identified with batch number, roll number, and shade number.

- When a panel needs to be replaced, the cutting operator checks the panel number and identifies the roll from the spreading sheet.

- After that, collect the fabric, check shade and quality defects, and spreads the fabric by following the same fabric way and grain line.

- Then, as per the panel size, recut operator collects the approved pattern and cuts one piece by following the same pattern.

- Next, put the numbering sticker by taking it from the defective panel, and the panel is handed over to the quality team for inspection.

- The Standard Operating Procedure (SOP) should be available in the recut area.

Sharp Tools Management

- All sharp tools must be registered in the official inventory including all the details such as tool type, serial number, and acquisition date.

- Implement a tracking system to monitor the movement and usage of each sharp tool.

- Regularly update the tool status to reflect changes in ownership or location.

- Conduct routine inspections to ensure the sharp tools are in good condition.

- Establish designated storage areas for sharp tools.

- Provide comprehensive training on the proper use and handling of sharp tools. Ensure all personnel are aware of safety protocols related to these tools.

Commonly used sharp tools in cutting– Cutting blades, scissors, cutters, clamps, pins, gloves, etc.

Continuous improvement in cutting: garment Cutting and Quality Management

Continuous improvement is a tool that showcase the significance of quality management system. It is crucial to set up policies and procedures for continuous improvements like reduced defects, improved processes, and enhanced productivity. Using tools such as Hoshin Kanri, Poka-Yoke, RCA, Kaizen, etc., is essential to ensure progress in operational and quality parameters, demonstrating the effectiveness of the QMS.

Common Problems in Cutting Operation

- Size sticker/numbering mistake

- Different shade mixes up at spreading

- Shade variation after panels replacement/overlap

- Asymmetrical panels shape because of cutting at different angles in same cake.

- Bundle card information mistake

- Wrong shrinkage of patterns in marker.

- Notch/cut mark missing.

- Panels shortage in bundle

- The fabric length and diameter measurements fall short.

- The warehouse supplied the incorrect fabric.

Best Practices in Cutting Operation: Garment Cutting and Quality Management

Cutting Operation:

- Implement modern technologies, such as an online reporting system with a display board, to showcase real-time analysis of operations and quality.

- Prior to spreading, ensure the availability of fabric continuity card, mini marker, and approved sample.

- Inspect panels 100% for quality.

- Perform a cutting accuracy check using a hard paper pattern, document the results, and analyze them.

- Apply a numbering system to panels to avoid color shading.

- Implement color coding to prevent color contamination for light-colored fabric.

- Availability of all the running style patterns.

- Availability of pre-shrunk machines for quick relaxation

- Usage of polybag for light color fabric

Leftover Fabric Storage:

- Store fabric leftovers with complete details, including roll number, cut number, shade number, etc., for easy tracing during panel replacement of defective panels.

- Use a hard paper pattern when replacing defective panels.

- Designate specific staff for panel replacement.

Cutting Tools:

- Use a magnetic toolbox to avoid contaminating panels during blade sharpening.

- Allocate the correct number of clamps during panel cutting.

- Ensure cutting operators use personal protective equipment (PPE) during cutting operations.

Cut Panels Inspection:

- Availability of defects display board at inspection table.

- There should be different boxes for keeping panels based on their status, such as Passed, Waiting for Inspection, and Rejected.

- Regular knowledge-sharing sessions for all checkers.

In conclusion, the success of textile businesses relies significantly on the cooperation between quality management systems and garment cutting. In addition to increasing operational effectiveness, a dedication to cutting precision and meticulous quality management procedures fortifies the brand’s standing in the highly competitive marketplace. In the fast-paced and competitive world of fashion and apparel, the textile industry’s ability to stay ahead of the curve will depend on its adoption of modern technology and quality assurance procedures.

About the Author

Presented By: Mohaiminul Islam, a professional in Quality Management, currently serving as a QA Technologist at CSS-George at ASDA. Mohaiminul holds a degree in Textile Engineering from Textile Engineering College, Chittagong, and a Postgraduate Diploma in Textile Industry Management (TIM) from Butex. Apart from his professional endeavors, Mohaiminul is actively involved in sharing his expertise by contributing to online articles.

- You may love to read: Best Practices in Apparel Industry.