Sewing Defect

We call sewing defects that produce in the sewing section. A defect is a barrier to quality, so we all want to reduce defects. To reduce defects, we need to know the root causes and corrective actions need to be taken. Here we have collected the most common defects always created in sewing. Hope this writing would help you to know Sewing Defect names with Root Causes and Corrective Actions.

Sewing Defects with Root Causes and Corrective Actions

| Name of Sewing Defect | Root Causes of Sewing Defects | Corrective Actions of Sewing defect |

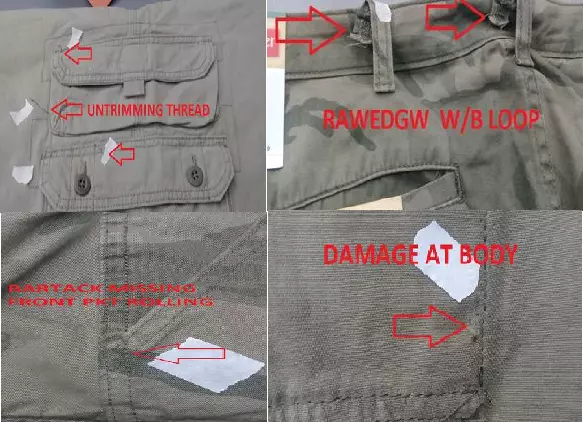

| Uncut Thread | Sewing machine wiper not used properly. Operator and helper do not cut their extra thread in their own operation. | Need to use a sewing machine wiper.Need to inspire to cut extra thread in their own operation. |

| Skip Stich | If don’t use the proper needle and Sewing thread according to the fabrication.If proper loop formation did not happen during the sewing.If a defective needle has been used. | Need to use the proper needle and sewing thread according to the fabric. Need to use a good Rotary hook and looper in the sewing machine.Should not use the defective needle. |

| Puckering | 1. If the sewing allowance is not maintained properly. 2. If do not maintain pattern marking properly. 3. If the fabric cut panel is matched properly. | 1. Sewing allowance should maintain properly. 2. Pattern marking should do properly. 3. Fabric cut should handle proper way. |

| Broken Stich | If excessive thread tension on the sewing machine. Needle frictional heat during the sewing. Poor Quality sewing thread used. | 1. Sewing machine thread needs to be checked and set according to the operation. 2. Need to use good quality thread. 3. Need to use proper needle and sewing thread according to fabric |

| Uneven Stitch | 1. If the sewing allowance is not maintained properly. 2. Due to poor handling of sewing operator. 3. Proper sewing machine guide not used according to the operation or existing guide mistake. | 1. Required training for unskilled sewing operators. 2. Need to use a proper sewing guide. |

| Pleat | 1. Cut panel measurement up/down cutting department. 2. Sewing operator method problem. | 1. 100% cut mark follows. 2. Required training for unskilled sewing operators. |

| Raw Edges | 1. If a proper sewing guide is not used. 2. Cut panel measurement bigger than required measurement. 3. Do not use the actual folder. | 1. Have to use a proper sewing guide according to the operation. 2. Cut measurement should be okay. 3. Need to use actual folder according to cut panel measurement. |

| Open Seam | 1. Sewing allowance not maintained properly. 2. Incorrect threading. 3. Tension of sewing thread not right. | 1. Sewing allowance should maintain properly. 2. Sewing thread has to select according to fabric type. |

| Needle Mark | 1. If the needle tip point is less sharp. 2. If any wrong stitch is open. 3. Sewing operator unconsciousness. | 1. Need to check needle sharpness and have to change the defective needle. 2. Sewing operator has to be more attentive in their work. |

| Fabric Damage | 1. Unconsciousness of sewing operator and helper when she/he cutting extra thread. 2. If the needle tip point is sharpness less. | 1. Have to be more attentive when removing the extra thread. 2. Defective needles have to change immediately. |

| Center Front Zipper Pointy | 1. If the zipper does not adjusts properly with the front of the jacket. 2. Zipper length bigger than the front part panel. | 1. Center front zipper should be adjusted properly. 2. Zipper length should be okay. |

| Join Stitch | 1. Thread breaking during the stitching. 2. Thread ending in the bobbin case and not removed the incomplete stitch. 3. Stitching cut during the thread trimming. | 1. Have to use good quality thread. 2. Thread has to rebind before ending sewing thread in the bobbin. 3. Have to be more conscious about thread trimming. |

| Down Stitch | 1. Stitching alignment is not followed properly. 2. Unconsciousness of the sewing operator. | 1. Have to stitch over the actual alignment. 2. Have to be more attentive during stitching. |

| Button Camp out | Snap Button Machine adjustment is not okay. | Snap button machine pressure needs to be adjusted with fabric and button type. |

| High-Low Positioning | 1. Pattern marking not followed properly. 2. Handling problems of the sewing operator. | 1. Mark has to follow properly. 2. Points have to adjust according to marking. |

| Bartack Missing | 1. If bar-tack placement is not okay. | Bar-tack placement should be proper. |

| Zipper wavy | 1. If zipper adjustment is too much tight. 2. Zipper mark and body cut mark is not adjusted properly. 3. Zipper measurement and body length measurement not adjusted. | 1. Zipper adjustment should be properly. 2. Zipper mark and body mark should to be matched. 3. Zipper measurement and body measurement should be proper. |

| Part Shading with each other | 1. Cutting not according to shade wise. 2. Cutting quality did not check shade during fabric spreading. 3. Issue – Input not checked in the sewing line by Quality. | 1. Fabric should be cut shade-wise. 2. Fabric shade have to check during fabric spreading 3. Issue –Input has to check on the sewing floor. |

| Off Shade | Washing is not done properly. Shade segregation is not done properly after wash and Finishing | Shade must be checked before dispatching garments from the washing factory. Off shade goods should be rewashed to bring up to the mark. |

| Spot | 1. Sewing machine not cleaned properly. 2. Garments kept on the floor and dusty area. 3. Sewing machine oil leakage. 4. Oil leakage on the machine. | 1. Machine needs to clean every day. 2. Garments must not keep on the floor. 3. Oil leaked machine need to changed. 4. Hand gloves need to use during light color garment production. |

Sewing Defect with Root Causes and Corrective Actions