Classification of Yarn in the Textile Industry

Yarn classification in textile spinning is a great topic. Without yarn classification, you can not define what type of yarn it is. Yarns may be classified supported length of fibre gift and range of elements gift. consistent with the length of fibers gift in yarn.

Yarn are generally classified as staple/spun, yarns, or continuous filament yarn. small stuff incorporates staple fiber assembled and certain along by twist to supply the desired characteristics like strength, handle, and look

Basic Yarn Classification in Textile Spinning

- Spun Yarn

- Filament Yarn

- Novelty Yarn

Classification of yarn according to the number of parts in Yarn

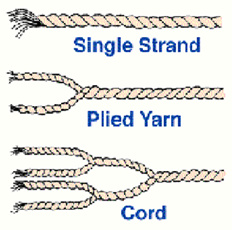

- Simple Yarn

In the construction of easy yarn, just one quiet fiber is employed. the way during which the fibres square measure twisted are similar throughout the length of the yarn. Yarns square measure referred to as easy, ply, or cable depending upon the number of strands they contain. - Single Yarn

In this, a variety of fibers square measure twisted along into an eternal length. The yarns consist of one quite fiber. this sort of yarn is the one typically found in most traditional materials for wear and house use and functions.

- Ply yarn

Two or over 2 single yarns square measure twisted along to create a ply yarn. These yarns square measure referred to as multiple-strand yarn. If 2 single yarns square measure twisted along, the ensuing yarn is understood as thick yarn. If 3 square measures are twisted along thick yarn and so on. - Cabled Yarn

It is created by a 3rd twisted operation, during which ply yarns square measure twisted along. Some forms of stitching threads and a few ropes belong to the current cluster. Cords square measure rarely utilized in attire cloth, however utilized in industrial weight materials. - Double Yarn

This consists of 2 or a lot of single strands treated joined within the weaving method, however the strands aren’t twisted along. These square measures are used for decorative results because the low-twist yarns manufacture luster and softness.

Classification according to the twist direction

Yarn twist: Twist is that the spiral arrangement of the fibers around the axis of the yarn. Revolving one finish of the fibre strand whereas the opposite finish is command stationary produces a twist. Twist binds the fibers along and offers the small stuff strength. it’s how to vary the looks of materials. The amount of twists is stated as turns per in.. they need a right away relating the value.

The twist is that the spiral arrangement of the fibers round the axis of the yarn. Revolving one finish of the fibre strand whereas the opposite finish is command stationary any produces twist. Twist binds the fibers along and offers the yarn. The higher twist yields lower productivity.

Direction of Twist, The direction of the twist is delineated as

- s-twist and

- z-twist.

A yarn has an S-twist if once commanded during a vertical position, the spiral makes sure the direction of the slope of the central portion of the letter “Z”. The Z-twist is the normal twist used for weaving yarns. The bulk of single yarns are spun with a twist in the Z-direction.

The Amount of Twist varies with

1. The length of fibres

2. the dimensions of the yarn

3. The meant use

Classification of yarn according to their use

- Weaving Yarn: It is being used in the weaving process in order to make woven Fabric.

- Knitting Yarn: Produce Knit fabric through the knitting process. More stretchy than the weaving fabric.