Difference between Lining and Interlining | Lining and Interlining Fiber Types

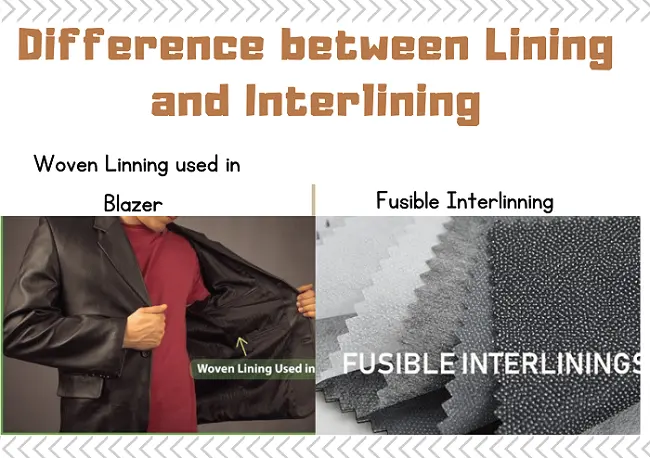

Lining and Interlining Both are being used in the garments industry as cloth trimming. Both trims are attached to the garment part through the fusing process, sewing process, or ironing. We use them on the inner side of the garment, not visible from the top side. Lining and Interlining both are nonwoven fabrics, the role is to reinforce some particular areas like collar, hem, cuffs, jacket, and coats. The terms lining and interlining are used frequently during the garment-making process, yet occasionally these vital components of clothing can be confusing. Both items’ attachment operation is under the sewing department. Nonetheless, these clothing items have quite distinct responsibilities. In general, the lining is used to cover the inside of clothing, whereas interlining is inserted between two layers of fabric. These components’ primary functions are to keep clothing comfortable and in form. The differences between lining and interlining will now be discussed.

Linning

To provide a garment shape, structure, and support, a layer of cloth or other material is inserted between the exterior fabric and lining. Cotton, wool, polyester, nylon, or a combination of these materials are just a few of the materials that can be used to make interlining. A layer of fabric that is sewn into the interior of a garment, usually the bodice, sleeves, skirt, or pants, is referred to as lining in the clothing industry. The lining is used to provide clothes structure, form, and comfort. It also serves to hide a garment’s inner construction and shield the exterior fabric from sweat and skin oils.

A range of materials, such as silk, polyester, cotton, rayon, or a composite of fibers, can be used to create lining fabrics. The kind of lining chosen is determined by the type of clothing and the desired result. For instance, silk is frequently used for expensive clothing, such as evening dresses, whereas polyester is a more cost-effective choice for casual clothing.

Lining fiber types

Lining can be used to give ornamental or contrasting details to a garment, such as a strong print or a splash of color, in addition to its functional advantages. Warp knit linings are an option, however, they are primarily woven and constructed of a viscose, polyamide, rayon, polyester, cotton, and wool blend.

What is Interlining?

An interlining is a layer of cloth positioned between a garment’s lining and exterior fabric. It is used to provide specific garment components, such as collars, cuffs, waistbands, and lapels, with more structure, shape, support, and stability. Fusible and sew-in interlinings are two examples of the several types available. In order to adhere the interlining to the outer fabric, fusible interlinings have an adhesive layer on one side that is activated by heat and steam. The garment is stitched to the sew-in interlinings.

The type of interlining used can also vary based on the desired outcome. For instance, a light interlining can be utilized to give a collar shape, whereas a stronger interlining can give a waistband structure. Cotton, wool, polyester, and nylon are a few fabrics that are frequently used as interlinings.

Interlining fiber types

During interlining, materials made of nylon, cotton, polyester, wool, and viscose are used.

The purpose of interlining

- The main purposes of interlinings are to add strength/support, stability, and shape retention.

- t functions as a composite and stabilizes the outer shell against any distortion under stress when fused to the outer shell cloth.

- enhances the fused laminate’s appearance and texture.

- maintains the shape of the fused portion throughout use and aftercare.

- increases the fused part’s lifetime

Differences between Lining and Interlining

| Parameters | Lining | Interlining |

| Placement | Used inside of clothing or clothing parts that are close to the skin. | Used between two fabric layers. |

| Attachment | Via stitching, attached. | Either sewn on or heated and pressed into place. |

| Finishes | Finishing is optional. | It may occasionally be necessary to add a shrink- or crease-resistant treatment to enhance its qualities. |

| Coating | There is no coating applied. | The fusible interlining inside the surface is coated. |

| Purposes | To improve the garment’s hang and comfort. | To maintain the genuine contour of the garment’s components. |

| Use | Blazer, jacket, coat, overcoat, trousers, etc | Cuffs, collars, and the front part of shirts and coats |

- Author: Susmita Sarkar

- B. Tech in Apparel Production and Management from GCETT, Serampore.

- Master’s degree in Fashion Technology at National Institute of Fashion Technology, New Delhi, India.