What is AQL?

AQL is an Acceptable quality level, a statistical quality control tool, a sampling method, and a technique used all over the world and used for batch/lot wise quality inspection as an alternative to 100% quality control inspection. AQL chart defines the details information about sampling, how many to be inspected, how many are under acceptable, etc.

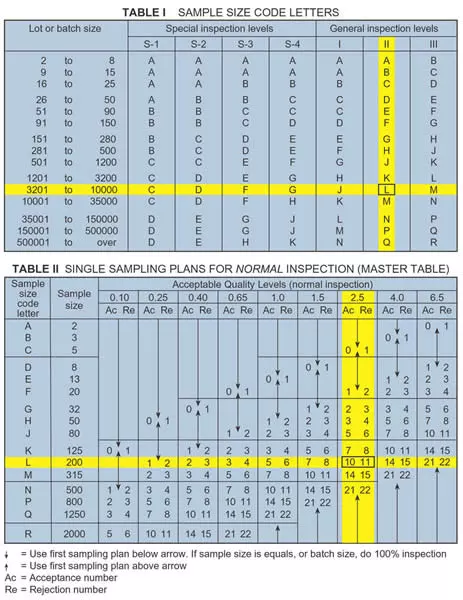

AQL Chart

AQL chart is an AQL table, that mentions the number of sample sizes based on lot size, easy to define inspection quantity, and result. AQL inspection level should be set by the buyer/ brand, so the quality inspection team can follow the same. There are basically two charts/tables that you need to understand. The first one tells you which code letter to use as per inspection level. Then, in the second table, the code letter will give you the sample size and the maximum number of defects that can be accepted. Now, we’re going to go through these two tables step by step. In the first table, you should know these two parameters. The first one is the lot size and letter number under inspection level. And the second table has the quantity of acceptable against every letter. And there is also an acceptable quality level in the 2nd table like 1.0, 1.5, 2.5, 4.0, etc. So two things are factors in the AQL chart, those are inspection sampling level and acceptable quality level.

Example: If a lot has 3250 pieces of garments; the general sample inspection level- ||, and the acceptable quality level is 2.5. So from the first chart, the letter comes L, so the inspection quantity will be 200 pieces, and the acceptable defects number will be 10.

AQL inspection in the Garments industry

AQL inspection is an audit to accept or reject a lot based on the statistical sampling process. The sample size is determined based on the AQL label and lot qty. There could be so many reasons behind the sample base shipment AQL inspection. 100% inspection is a more expensive, lengthy, and tedious job. If 100% of garments reopen for inspection, will make defects, and re-packaging will show a product as older. So, the buyer QC follows the AQL sampling method to do garments shipment inspection. In mass production, 100% of finished garments are not inspected at the final shipment inspection. Instead, a sample-based inspection is carried out by the buyer representative QC. Based on the AQL level and acceptance level, an inspection report is to be published by the buyer inspection QC. If the inspection cannot qualify to pass as per the AQL level, the vendor is asked to do a rework of the lot. Shipment is not allowed without qualifying for AQL inspection, AQL inspection report is in an inspection certificate (IC).