Effect of Bleaching on Denim Fabric of Denim Wash, How Colorfastness rate is affected by different bleach percentages?

Introduction: Bleaching is the most important pre-treatment process for wet processing. Before dyeing fabric goes through this process to achieve adequate shade. Like de-sizing & scouring, the bleaching process also has a certain impact on the fabric. This Process to done to remove colour, extra dirt & dust, oil & grease marks from the fabric. I present the Effect of Bleaching on the Denim Fabric of Denim Wash and how it affected in colorfastness test results.

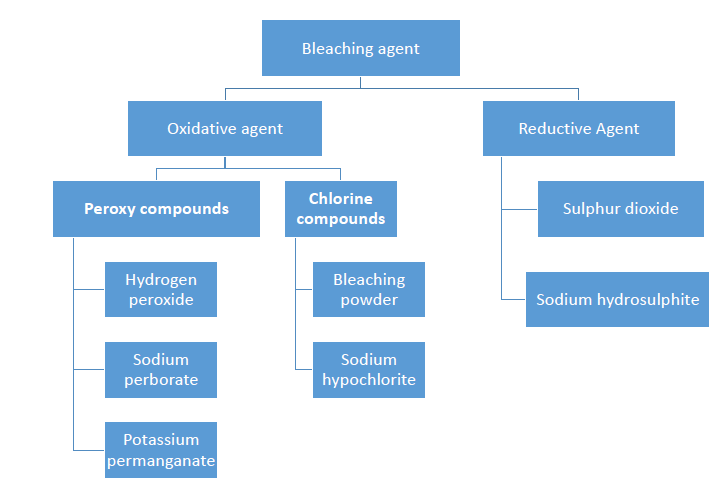

Broadly, There are two bleaching agents; 1. Oxidative Agent and 2. Reductive Agent

For denim, all this wet process is done on the garment instead of the fabric. Depending on the shade of the final pair of jeans or a jacket the wet process varies. As the bleach process affects the fabric it will affect almost similar on the denim.

Bleaching Process on Denim Fabric:

For this study, a denim fabric is considered & makes 6 leg tubes. The steps followed in the leg tubes are Desize → Bleaching→ Neutralization → Clean Up→ Silicon & Softener.

Desize: A front-loader washing machine needs to be filled with 50-liter water. Put the below chemical in a certain percentage. Need to run the machine for 25 min & the temperature should be 45 degrees C.

Lubricant (2gpl) + Wetting agent (2gpl) + Anti back stain( 2gpl)

Bleaching: Different bleaching concentration is prepared & applied to the denim leg tube.

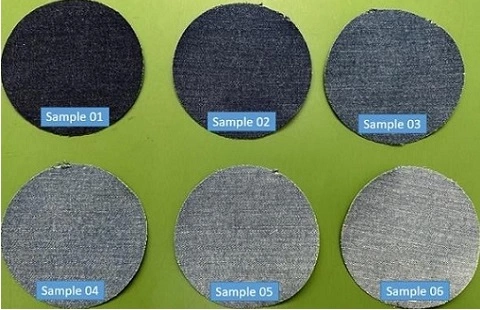

The cycle time of each sample is kept constant. For the 1st sample concentration of liquid bleach is 15 gpl. Double the concentration on each sample. 6th sample is of 90gpl. Increasing the concentration has an impact on the cellulosic fabric & the depth of shade is reduced to a certain level.

- Sample 01- has the darkest shade & bleach concentration is minimal.

- Sample 06- Have the lightest shade & bleach concentration is maximum.

| Sample no | Component | |||

| Water (Lt) | Liquid bleach(gm) | Liquid bleach(gpl) | Cycle Time (Min) | |

| Sample 01 | 30 | 450 | 15 | 10 |

| Sample 02 | 30 | 900 | 30 | 10 |

| Sample 03 | 30 | 1350 | 45 | 10 |

| Sample 04 | 30 | 1800 | 60 | 10 |

| Sample 05 | 30 | 2250 | 75 | 10 |

| Sample 06 | 30 | 2700 | 90 | 10 |

- Neutralization: The bleaching process is active in Acidic pH. So it needs to be a neutral pH value. This process will continue for 10 min at 45 degrees C.

- Clean up & silicon softener is the process of cleaning the surface & increasing the hand-feel of the leg tube.

How bleaching Effects on color fastness of denim:

A “grayscale” version of an image uses a mix of black and white to represent the “value” of the colors. Grayscale is used for visually evaluating changes in the color of textiles resulting from colorfastness tests. There are two types of grayscale – one for assessing color change and another for staining. The color change grayscale consists of nine pairs of grey-colored chips, in grades ranging from 1 to 5. They are manufactured strictly in accordance with ISO 105- A02 and AO3.

- Sample 01- Dry fastness rating- 3-4 & wet fastness rating 1-2.

- Sample 06- Dry fastness rating 4-5 & wet fastness rating 2-3.

| Sample no | Liquid bleach(gpl) | Colour fastness rate | ||

| Dry | Wet | |||

| Sample 01 | 15 | 3-4 | 1-2 | |

| Sample 02 | 30 | 4 | 2 | |

| Sample 03 | 45 | 4 | 2 | |

| Sample 04 | 60 | 4-5 | 2-3 | |

| Sample 05 | 75 | 4-5 | 2-3 | |

| Sample 06 | 90 | 4-5 | 2-3 | |

Conclusion

Denim is an indigo predominantly cotton fabric. Bleach is a process of removal of dye from the garment. Increasing the amount of bleach percentage in the process will give different shades. The lower percentage of bleach gives a dark shade & higher percentage will give a lighter shade. Depending on the shade requirement for a particular garment technicians use the bleach percentage in the washing recipe.

It has been found that color fastness also has a relation to bleaching. Bleaching helps to increase both the colorfastness, Dry colorfastness & wet colorfastness. In lower bleach percentage the dry & wet colorfastness is 3-4 & 1-2. In higher percentages of bleach, the dry & wet colorfastness is 4-5 & 2-3.

- Author: Sourav Ghosh

- Masters from NIFT Delhi in fashion Technology, B.Tech in Textile Technology From GECTTS (2012-2016) EX- Arvind Mill

- Email: [email protected]

- You May Love to read: Difference Between Denim and Jeans

- Top 10 Denim Jeans brands in World

- 10 Interesting Facts about Denim and Jeans You need to know

- 7 Diverse Uses of Denim Fabric

- Denim Finishing using Laser Technology: Working Process