Fabric is an important and basic element in clothing and fashion. We cannot imagine the world of human Beings with fabric in the era. The fabric has to go through many processes and tests up to the finishing process. There are many types of fabric used for various purposes. Textile and Apparel merchandisers spent a huge time behind fabric sourcing. To make a cloth, first, you need to get needed a specific fabric. Then the cakewalk does a clothing business order. This article is about the details of the Fabric specification sheet.

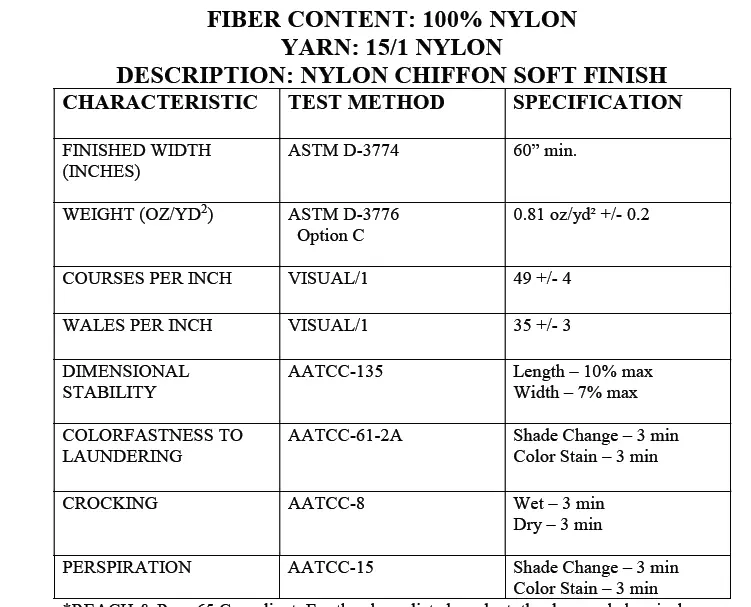

The fabric specification sheet has the details of the fabric from the technical aspect. It included the fiber origin, the weaving process, design, weight, finishing type, and all fabric testing applications. A long list is there as a fabric parameter in the spec sheet. Knowing fabric specifications is important for a fabric merchandiser, fabric technologist, and anyone related to fabric sourcing. The fabric spec sheet is a very important document in the textile industry. Here we’re sharing the Fabric specification sheet template below.

Quality Parameters considered in Fabric Specification Sheet

- Name of Fabric

- Thickness

- Fiber content

- Yarn Type

- Density (GSM)

- Weight (oz/yd2)

- Purity Level (SiO2 content)

- Total Width

- Finished useable width

- Warp Count (PCS/CM)

- Fill Count (PCS/CM)

- Weave type

- Finished type

- Resin Applied

- Dielectric Constant

- Loss Factor

- Insulation Strength

- Resistivity

- Thermal Expansion Coefficient

- Specific Heat

- Thermal Conductivity

- Textile Applied Expoxy

- Reinforced Expoxy

- PTFE Resin

- Filament Nominal Diameter

- Nominal Linar DensityθTexχ

- Nominal Twist(T/m)

- Dimensional Stability

- Colorfastness to Laundering

- Crocking; Wet and dry

- Perspiration

- Abrasion resistance

- Break strength.

- Tear strength

- Seam slippage

- Colorfastness to light

- Flammability*

- PH Value

- Twisting direction

Example of a Fabric Specification Sheet

| Fabric NAME | Quartz fabric |

| Thickness | 0.2mm |

| Density (GSM) | 216±13 |

| Purity Level (SiO2 content) | ≥99.99 % |

| Width | 100cm |

| Warp Count (PCS/CM) | 16 |

| Fill Count (PCS/CM) | 14 |

| Weave | TWILL |

| Resin Applied | EPOXY |

| Dielectric Constant | 3.78 |

| Loss Factor | 0.0002 |

| Insulation Strength | 5×10⁷V/m |

| Resistivity | 1×10¹⁸Ω.cm /1×10⁶Ω•cm (20℃/1000℃) |

| Thermal Expansion Coefficient | 5.5×10-7cm/cm•℃ (20℃-320℃χ |

| Specific Heat | 670J/kg•℃ (20°C) |

| Thermal Conductivity | 1.4W/m•℃ (20°C) |

| Textile Applied Expoxy | 1.0% |

| Reinforced Expoxy | 1.0% |

| PTFE Resin | 4-6% |

| Filament Nominal Diameter | 7-12μm |

| Nominal Linar DensityθTexχ | 13.5~2400 (Hollow Yarn 51~600) |

| Nominal Twist(T/m) | 50~130 (Hollow Yarn 50~75) |

This is just an example, these are the factors considered in the Fabric specification sheet.

You may love to read: Specification Sheet in Garments Industry