Cost stabilization depends on the proper utilization of every resource in the garments manufacturing industry, henceforth being competitive to sustain the market share and cope with the newest competitors, it is necessary to deliver quality products in time at a reasonable price to the customer.

Poor resource utilization affects every aspect of production as well as the cost of production. In garment manufacturing companies the two basic types of waste are material waste and time waste. In order to maximize profit margin, it is necessary to minimize all types of waste.

As the sewing section is being called a pacemaker in the garment manufacturing process, today’s topic is to have a detailed discussion on the Quick changeover philosophy.

Formally as defined in manufacturing terms, a changeover is simply the amount of time taken to change a piece of product from producing the last good piece of a production style/lot to the first good piece of the next production lot. The changeover is the gap between the last good piece output of the previous order from the last machine (Output) of a line and the first good piece output of the next order/style from the last machine of the line. It means the “X” style’s last pics output was produced at 10.30 AM on 16-Jan-22, simultaneously new style’s feed started in the same line. The new style’s first good piece output was 5.30 on 16-Jan-22, so the changeover time was 6 hours.

Why Quick Changeovers?

Here are many reasons Garments companies should focus on reducing the time it takes to changeover their product and processes.

- The first reason for the quick changeover is that it leads to a reduction in lead time. You can see, that quick changeover leads to increased velocity. In other words, you’re able to create value faster when your machines are running and not sitting idle.

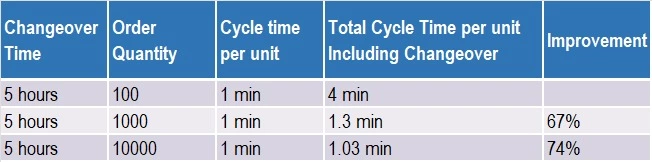

- Another reason quick changeover reduces lead time is related to lot sizes. You see, when lot sizes are reduced the lead-time, or the time from when a customer orders a product until it’s received, is also reduced.

- Next, as a result of this improved flexibility and reduced lead time quick changeover also improves on-time delivery performance.

- Quick Changeover also enables a dramatic reduction of inventory which reduces inventory carrying costs and increases cash flow

- Finally, quick changeover enables heijunka or production leveling.

8 Steps to Quick Changeover

- The first step to quick changeover is to “Document reality”. Many companies have found a video camera to be the best tool to make this happen.

- The second step has us “Separating” what we refer to as “internal and external tasks”. Again, we’ll discuss this in great detail in an upcoming module but the quick explanation is that internal tasks can only be done when the machine has stopped running while external tasks can be done while the machine is running. For example, you can gather your tools and complete paperwork while the machine is cycling a part.

- The third step has us “Shifting internal activities to external activities”. In other words, we want to do as much as we can while the machine is running so that when it does stop we can quickly get it back up.

- The fourth step has us “Streamlining all external tasks”. In other words, even though the machine is running we still need to be as efficient as possible when completing external tasks like paperwork and preparing for the next changeover.

- The fifth step is often not discussed when teaching SMED or quick changeover but is absolutely necessary. This step has us “Identify parallel tasks”. Two people, working in harmony with one another, can go much faster than one person working by themselves.

- Next, the sixth step has us “Streamlining internal tasks”. In other words, once the machine is down and isn’t producing parts we need to find ways of getting it back up and running as fast as possible. There are many different techniques and methods to go about this… and we’ll share many of these with you in an upcoming module.

- The seventh step is another extremely important one that often gets glossed over by many teachers of quick changeover… and this step has us “Practicing” the new and improved changeover method.

- Lastly, the eighth and final step has us “Documenting the new standard” in such a way as to ensure it’s done in a repeatable and reproducible manner.

What is Changeover Time

Changeover Time is the elapsed time between the last good previous product and the first good next product at the right speed. Changeover Time is the summation of Setup Time and Startup Time. Setup Time is the time to adjust or replace machine parts to accommodate the new product. Startup Time is the time to bring the process up to the right speed and quality.

When setups can be done quickly, they can be done as often as needed. This means companies can make products in smaller lots, which has many advantages:

- Flexibility: Companies can meet changing customer needs without the expense of excess inventory.

- Quicker delivery: Small-lot production means less lead time and fewer customer waiting times. Better quality: Less inventory storage means fewer storage-related defects.

- Quick Changeover also lowers defects by reducing setup errors and eliminating trial runs of the new product.

- Higher productivity: Shorter changeovers reduce downtime, which means a higher cloth/ garment productivity rate.

The need for Quick Changeover in the apparel Industry

- It leads to a reduction in lead time.

- Helps and supports small batches.

- Reduces Inventory, less WIP in the process.

- Makes you flexible to take orders of any size.

Finally, The quick changeover (QCO) must needful thing in this competitive market to survive as a garments manufacturer and supplier. Nowadays manufacturers are putting effort into making the quick changeover understanding its importance.

Courtesy: Mrityunjoy (Joy) Bandyopadhyay

- References:

- https://www.coursehero.com/file/p2m98o2/The-first-step-to-quick-changeover-is-to-document-reality-Many-companies-have

- https://www.rmgtech.in/p/smed-trainingppt.html#:~:text=Another%20reason%20Quick%20Changeover%20reduces,but%20waiting

- %20or%20queue%20time.

- https://opexlearning.com/resources/about-peter-abilla/what-is-smed-and-quick-changeover

- https://www.scribd.com/document/317812156/2b-QCO-Overview

- https://copbok.com.br/hjnc/how-to-reduce-setup-time-in-manufacturing

- https://pe.gndec.ac.in/sites/default/files/03-Jaskaran%20Singh.pdf