Needle management is the most important thing for product Safety in the Garments Industry. In the garments industry, the needle stands out as an indispensable component, serving as the primary instrument in stitching fabrics together. Managing needles effectively within the garment industry is not just a matter of organizational convenience; it’s a critical aspect that influences product quality, worker safety, and operational efficiency. In this article, we present Needle Management Procedures in the Garments Industry.

Needle Management Procedures in the Garments Industry

- The spare needle must be kept in a designated sub-store where entry is restricted for everyone except the responsible Needleman.

- Each and every sewing machine should be fitted with an appropriate needle to ensure minimal breakage.

- Only the designated mechanic can install or reinstall a sewing needle in the sewing machine.

- The operator should hold no spare needles. For example, one needle for a single needle lock stitch machine operator, and alternatively, two needles for a double (or twin) needle lock stitch machine operator.

- When a needle breaks, the operation must be stopped, and the section supervisor must be informed. A new needle (replacement) should not be issued until all parts of the broken needle are found.

- Efforts should be made to search for all fragments of the needle visually or by means of hand held metal detector or strong magnet bar. All the WIP (work in progress) garments of that workstation including the total workstation with the sewing machine throat plate, feed dogs and bobbin case should be searched carefully.

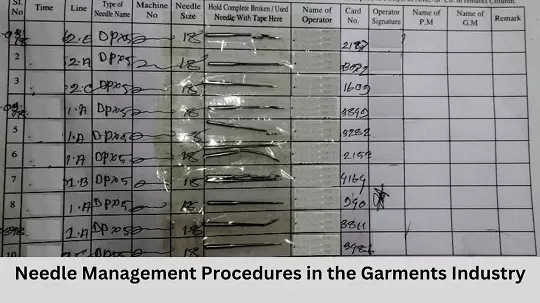

- All the fragment of broken needle which is found by searching is to be kept in a needle pot and sent to needle sub-store. All the fragment should be mounted on cello tape and checked by the Needleman against a whole needle to prove that all parts have been found.

- If it is proven that- all the fragment of the needle is found, Needleman should attach the cello tape along with the broken parts of needle in broken needle record album and issue a same needle (new) as a replacement.

- If it is proven that- all the fragment is not found, line-chief and in-charge should be informed and above mentioned (f) procedure should be followed again. If the remaining part (s) is found, it should be taken to needle sub-store by needle pot and the Needleman should follow the above mentioned (h) procedure.

- If it is proven that some portion is still missing, the designated box should be collected from needle sub store, and all the WIP (work in progress) garments of that workstation should be isolated in that box and carried to conveyor metal detector machine for advanced searching. In the meantime related work station and surrounding area must be checked again with a needle sweeper and/or hand-held metal detector/magnet to ensure the place metal free. Only after ensuring the workplace free from metal contamination, a new needle should be taken and work should be restarted.

- Conveyor metal detector machine operator should check all the isolated garments (from box) by passing through the metal detector machine and extract the contaminated garments. Rest non-contaminated garment(s) should be send back to the production process.

- All the parts of the extracted contaminated garment(s) should be rechecked with a hand-held metal detector. If the metal part(s) is found, it should be extracted and checked again with the conveyor metal detector. If the garment(s) is proven metal-free, it will be sent back to the production process. Otherwise, it should be locked in the designated red box.

- If any contaminated garments is not found in the total isolated garments, all the isolated garments should be locked in the designated red box.

- Before checking these isolated garments, the conveyor metal detector machine must be calibrated with a ferrous test card. The hand-held detector also must be calibrated using the ferrous test piece before being used every time.

- Needleman should attach the cello tape along with the incomplete, broken parts of the needle in a separate record format mentioning the number of isolated garments, which has been checked with the conveyor metal detector machine.

- Used needles should be kept in a locked box and every six months we send them back to our supplier for recycling.

- The above-mentioned needle policy is also applicable to every type of tag gun needle.

- Any new employee (sewing machine operator/ tag gun user/ section supervisor) must be explained on the broken needle policy before starting his/her work.

Conclusion

In the garment industry, Effective needle management procedures not only ensure the quality of the final product but also safeguard the well-being of workers and optimize operational efficiency. By implementing systematic inventory control, proper storage, regular maintenance, and employee training, the garment industry can uphold high standards while promoting a safe and productive work environment.

- You would love to read: 12 Steps to Put and Replace Needle in a Sewing Machine

- Different Parts of a Needle