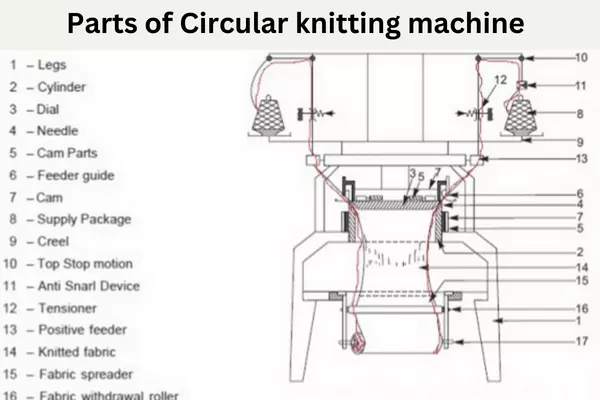

Circular Knitting Machine is used to produce seamless tube-shaped fabric in the knit garments industry. The knit garments manufacturing process is a common machine that can produce fabric at a lower price. But the circular knitting machine has many types. Basically, the machine is circular in shape, so the name is Circular knitting machine. The machine has a cylindrical bed with a series of needles around the circumference of the machine. Circular knitting machines can produce Single jersey fabric, double-jersey fabric, rib fabric, interlock, and jacquard fabrics. Here I am presenting the Different Parts and Functions of the Circular Knitting Machine, which you would love to read.

Circular Knitting Machines Parts and their Functions

Circular knitting machines are used to produce knitted fabrics by looping yarns together in a circular pattern. The machine consists of various parts, each of which performs a specific function. Here are some of the key parts and their functions:

- Needles

- Needle Bed

- Cam System

- Yarn Feeders

- Sinker

- Fabric Take-up Roller

- Tensioner

- Stitch cam

- Lubrication system

- Needles: The needles are the most important part of the circular knitting machine. They are used to hold and manipulate the yarn as it is being knitted. The number of needles varies depending on the machine’s size and purpose.

- Needle bed: The needle bed is the surface on which the needles are mounted. It rotates to create a continuous circular motion, allowing the needles to knit in the round.

- Cam system: The cam system controls the movement of the needles. There are two types of cams: sinker cams and needle cams. Sinker cams manipulate the sinkers, which push the newly-formed loops down onto the needle bed, while needle cams control the needles themselves.

- Yarn feeders: Yarn feeders hold the yarn and feed it to the needles as they knit. The number of yarn feeders also varies depending on the machine’s size and purpose.

- Sinker: The sinker is a thin metal plate that rests behind the needles. It helps to guide the newly-formed loops over the needle and onto the fabric.

- Fabric take-up roller: The fabric take-up roller pulls the knitted fabric away from the needle bed as it is being knitted.

- Tensioner: The tensioner regulates the tension of the yarn as it is fed to the needles. Proper tension is important for producing even, consistent stitches.

- Stitch cam: The stitch cam controls the length of the stitches by determining how far the needles move in and out of the fabric.

- Lubrication system: The lubrication system ensures that the machine runs smoothly by keeping its moving parts lubricated.

Overall, a circular knitting machine works by feeding yarn to the needles, which then creates stitches in a circular pattern around the needle bed. The cam system controls the movement of the needles and yarn feeders to produce different types of knit fabrics.

- You may love to read: Difference between Single Jersey and Double Jersey Fabric

- What is Knitting | Types of (Knitted) Knit Fabrics

- Difference Between Warp Knitting and Weft Knitting