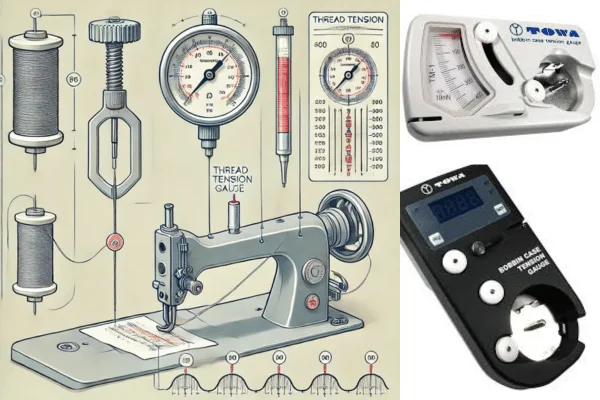

The scope of this procedure covers all the activities related to the embroidery section, such as recording and controlling thread tension. To define and determine all actions, steps, controls, and desired outputs of the embroidery section. This article is about the Procedure for the Thread Tension Gauge records in the Apparel Industry.

1. Responsibility :

- General Manager: Overall responsible for production and quality. Embroidery Incharge/Manager: Responsible for ensuring the process.

- Quality Manager & TQM: Responsible for ensuring quality and product safety.

- AGM: Ensuring compliance in the process

2. Definitions

This manual describes the procedure used for zero position adjustment, which is necessary when using the gauge for the first time, and also the procedure for measuring the thread tension.

3. Procedure for Thread Tension Gauge Record:

Zero position adjustment

- Take out the spring from the case by turning the knob and set it upright by holding the threaded.

- Turn the indicator nut clockwise so that the stopper comes into light contact with the knob.

- Note: If the stopper is already in contact with the knob. Turn the indicator nut counterclockwise to move the stopper away from the knob once after that bring the stopper into light contact with the knob by turning the nut.

Supplement: When turning the indicator nut, hold the stopper with your finger.

- Install the spring into the case.

- Supplement: If there is a gap between the lock nut and the knob, eliminate the gap by turning the lock nut before installing the spring into the case.

- Adjust the indicator nut position by turning the knob so that the reference line on the indicator nut will be aligned with the “0” Position. Then, lock the knob by tightening the lock nut.

Measuring the upper thread tension

- Wind the front end of the upper thread, which has been threaded to the presser around the hook of the gauge about two turns.

- Read the indication(tension) of the gauge while pulling it horizontally at a rate of 2-3 cm/second.

Supplement:

Tension values of typical kinds of threads are indicated below for your reference. Noted that the values will vary depending on the embroidery condition.

| Kind of thread | Tension value |

| Rayon (120/2) | 100-130 |

| Polyester spun (60/3) | 100-150 |

| Cotton thread | 20-35 |

Measuring the under-thread tension:

- Wind the front end of the under thread, which has been pulled out of the thread guide around the hook of the gauge about two turns.

- Place the bobbin case on a flat surface such as a table and hold it in place with a finger.

- Read the indication (Tension) of the gauge while pulling it slowly in the horizontal direction at the rate of 2-3 cm/sec.

- Supplement: The Tension value of a typical kind of thread is indicated below for your reference. Please note that the value will vary depending on the embroidery conditions.

| Kind of thread | Tension value |

| Rayon (120/2) | 100-130 |

| Polyester spun(60/3) | 100-150 |

| Cotton thread | 20-35 |

4. Record:

- Document the Thread tension gauge record in the quality check recording standard format.