Scouring is one of the pretreatment processes before dyeing and printing in a textile wet process. The term used in Textile indicates a natural impurities removal process from natural fibers and spin finish from the manmade fiber. We know natural fibers contain few portions of others elements besides their major composition. Similarly, synthetic fibers also have some impurities during the spin finish. These impurities create several problems like reducing fast wetting, producing spots, and hamper on final shades. So, the cleaning process to aim for the removal of such impurities is called Scouring. This article is about Scouring Process in Textile Industry.

Objectives of Scouring Textile

- To remove natural impurities from the textile material.

- To remove spin finish materials from synthetic fibers

- To increase absorbency

- To clean the fabric

- To improve Dye uptake

Natural fibers contain impurities in their structure, for example, the Composition of Cotton is given below:

- Cellulose : 88-96 %

- Pectin : 0.7-1.2 %

- Wax : 0.4-1 %

- Protein : 1.1-1.9 %

- Ash : 0.7-1.6 %

- Others : 0.5-1.6 %

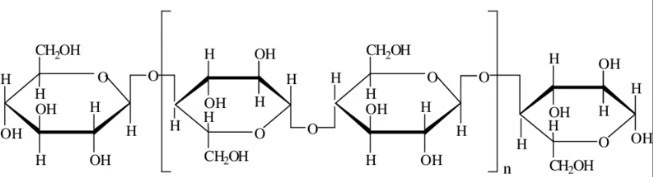

Structure of Cellulose

So Cellulose structure rotates alternatively 180⁰. The repeat unit of Cellulose is called Cellobiose. Though it seems theoretical Cellulose should be soluble in water but it is insoluble for the intermolecular bond.

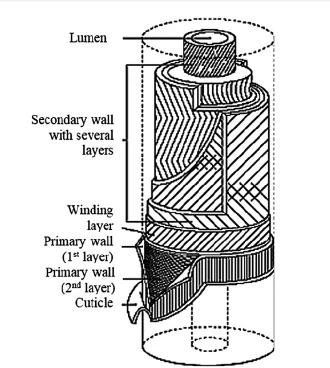

Cotton fiber Structure: The anatomy of Cotton fiber has major four components,

- Cortex (Outermost part, very thin),

- Lumen (Innermost part, Hollow portion),

- Primary cell wall (Position just below of Cortex),

- Secondary cell wall (Intermediate portion of fiber structure).

Maximum Impurities are on the Cortex and Primary cell wall.

List of impurities remove Scouring Process

Wax: Wax is Higher Aliphatic Alcohol/ Fatty Acid/Ester. It prevents the wetting property. So, Scouring is designed in such a way as to remove Wax or to crack the Wax structure to allow penetration and improve wetting.

Pectin: These are also carbohydrates as same as Cellulose but contain (-COOH) at the primary position rather (-OH).

Proteins: These are the polymer of Amino Acids.

Ash: Inorganic residues.

Scouring Agents: Na2CO3 is the first try for Scouring. As it is a mild Alkali. But later it found NaOH can be more suitable in absence of Air. So, at present NaOH or NaOH & Na2CO3 combinedly used for Scouring.

Scouring Agents and their functions

NaOH: Saponification of fatty acids. Hydrolysis of Ester & Covert it into Soluble form.

Emulsifier: Emulsify Hydrocarbons and Fatty Alcohol

Wetting Agent: Improve wetting

“Not only cotton but other fibers also undergo the Scouring process. Wool fibers also need Scouring as it also contains huge natural and additive impurities. But as Cotton is Cellulosic fiber and Wool is Protein fiber so the process and ingredients are different from each other Cellulosic fibers are sustainable in Alkaline conditions but decompose in Acidic conditions. But Protein fibers can withstand acidic conditions but cannot withstand Basic conditions.”

So, in Scouring:

- Wax removed by Saponification

- Esters are hydrolysed

- Fatty alcohols emulsify

- Pectin are converted (-COOH) to (-COONa)

- For Protein peptides bond breaks (-CONH-) to (-COOH+NH2)

- Ash is removed in Desizing and some are solubilized or precipitated, the remaining portion don’t affect much.

Typical recipes for Cotton Scouring:

- NaOH: 4% (owf)

- Wetting Agent: 1-3 g/l

- Emulsifying Agent: 1-3 g/l

- Sequestering Agent: 1-1.5 g/l

Machinery used in Scouring Process:

- Kier boiler

- J-Box

- Open width Scouring m/c.

- Author: Najmul Hossain

- Lecturer, Department of Textile Engineering

- Chittagong National Engineering College, Affiliated with the University of Chittagong

- LinkedIn: Najmul Hossain