Sewing is the art of garments. Every hole produced during the sewing process is a stitch. Stitching defects are sewing defects produced during the sewing process. As sewing is the only construction operation process for a garment, 80% of defects of garments is a stitching-related defects. Sewing is the major operation in garments manufacturing.

Stitching Defects produced in Sewing Process

SPI more or less

Stitches per inch in excess of + 2 or -1 from that specified in spec sheet construction, or if not the specification in construction specification, or if not specified, inappropriate.

Wrong stitch type

Stitch type or construction technique other than specified in construction specification or if not specified, inappropriate (i.e. lock stitching on a stretch seam without reinforcing). Ends of stitching, when not caught in other seams or stitching that are not backtracked, at least ¼” (2 or 3 stitches) on lockstitch or not latched back or condensed on chain stitch. (440,500,600 class).

Repair/ Mending

Mending stitching tide in less than ½ on each end of the repaired stitch. Repairs of chain stitch must be made with lockstitch or completely re-done with chain stitch. Defective stitching, insecure backstitch includes topstitching: broken/skipped stitches & railway stitches, defective hand-stitching.

Stitch Tension

Tight thread tension causes thread or fabric to break when normal tension is applied to total seam length. The seam must elongate 30%-35% beyond relaxed measurement.

Pleat in Stitching

Visible Pleat on fabric during the stitching process. Proper operator handling is the key to not getting a pleat in the sewing process.

Button stitching Defects

Buttonhole too large or too small for button functionality. Ragged edges caused by cut of dull knife causing fabric pulls. Misaligned or improperly spaced buttons. Thread shade that does not match the specified color.

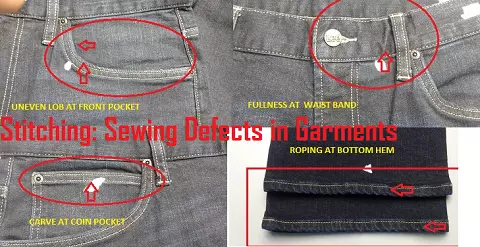

Stitching Defects of Bottom Hem

Hem sleeve uneven, twisted, or poorly sewn. High/ low bottom hem difference greater than ½” side to side or back to front. Binding, elastic, or hem.

Belt Loop Defects

Mismatching thread color, or thread color not according to specification. The number of loops is short according to the requirement. Loop slanted is also a major defect.

Collar/Collar Setting, Lapel and Cuff Defects

Excessive fullness, puckers, or twisting of a top collar. Collar points are distinctively ill-shaped or not uniform. Uneven collar points 1/4 “. Corded, piped, or other inserts trim conspicuously uneven, loose, or tight. Under-collar showing outside of the top collar, top stitch seam not balanced top to bottom ( rolled). Outside, attached thread ends over ½” loose threads not attached; Loose threads not attached.

Garments Construction in Sewing

Sewing Construction of Garments Any construction technique adversely affecting the performance of the product or not according to the spec. Spot shirring is not uniformly distributed. Neck rib and short sleeve cuff rib- width variance greater than +- 3/16”. Right versus left sleeve difference up to ½”. The collar is noticeably off-center when attached to the garment. Corresponding pockets horizontally uneven or misaligned in excess of ¼”. Excessively puckered or twisted hem. Uneven fronts at bottom ¼”. Under-facing shows on the top side of the garment.

Puckering

Puckering makes garments stitch ugly. So, the stitching is smooth and plain every customer like.

Additionally, You may love to read: Sewing Defect with Root Causes and Corrective Actions