Different Terms of Garments Manufacturing Processes

Normally, we use many terms in the garment industry. These terms are very important for learning. If we learn easily these terms, we can frequently use these terms. Some of the terms I will explain in the following, I Hope, will great helpful for informative learning. In this article, we discuss Different Terms of Garments Manufacturing Processes.

To work in the garments industry, you have to know to lot terms use there. Knowing them will make you technically sound. Different Terms of garments manufacturing Processes used in the production process and pattern-making.

Different Terms of Garments Manufacturing Processes

1. Across Shoulder

It is the measurement of straight across the back of the garment, from one shoulder point to another.

2. Across Back

It is the measurement of straight across the back of garments at the midpoint of the armhole seam from one side to the other.

3. Allowance:

When the garment is made by adding an extra dimension to the net dimension of the garment is called allowance.

4. Armhole:

One of the holes for your arms in a shirt & jacket. It is the measurement from underarm seams intersection point up to shoulder along the front armhole seam or edge.

5. Back Rise:

The back rise is from the crotch seam to the top of the waistband in the back.

6. Basic Block:

A basic block is a set of pattern pieces that form the simplest garment of a particular type of garment product. The pattern is made in accordance with the area of different parts of the human body without allowance & style.

7. Bar tack:

A bar tack stitch is basically a tight zigzag that is repeated back and forth over itself to reinforce a piece that is sewn together. It helps resist the fabric and increase the strength of the overall garments.

8. Basting:

Primary & temporary stitching before the final stitch with a view to facilitating accurate placement is called basting.

9. Blind Stitch:

It is a special type of stitch that cannot be viewed on the face side of the fabric & it only views the back side of the fabric.

10. Back Stitch:

This kind of stitch for sewing apparel which also do by machine.

11. Box pleat:

A box pleat is one of the most common types of pleats. It is formed when two equal folds of fabric are folded away from each other in opposite directions on the front of a length of fabric. The folds traditionally meet evenly at the center back but they don’t have to meet at the center. It can create a single box pleat or a grouping of box pleats, depending on the overall visual design. In addition, it is top-stitch or edge stitch a pleat to help maintain its form.

12. C.F Line:

The straight line is bottom to up vertically along the middle point of the body front of the shirt or jacket.

13. Crease:

It is one kind of folding & finger pressing the fabric along the gain or structural line.

14. Crocking:

Crocking is the act of tacking out color from the dry & wet cloth by rubbing or scouring.

15. Back Length (H.P.S)

Back length is the measurement from the high point shoulder down to the bottom edge of the garments.

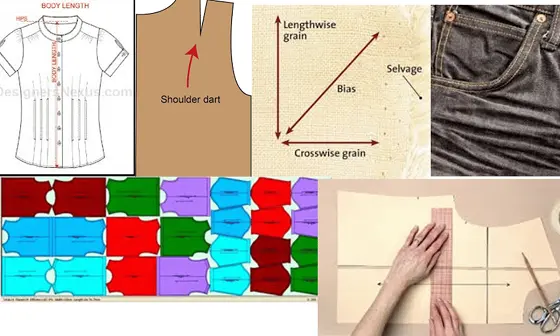

16. Dart:

Dart is the tightness of garments. It is made by stitching the fabric and sewing the fabric. It is used for removing wedges from the garment surface.

17. Fusing:

Fusing is the partial melting & bonding of fabric layers that are joined together by the fusion of an adhesive under heat and pressure.

18. Grain line:

The grain line is the pattern pieces that carry a line called the grain line. When pattern pieces are laid down during marker making over the cloth. The grain line should be parallel to the warp is the fabric is woven & Wales in knitted fabric.

19. Grading:

Different sizes of patterns are made from the master pattern of the garments is called grading.

20. Marker:

A marker is a thin paper that contains all the components of all sizes of a particular style.

21. Pattern:

The pattern is the hard pattern that is made by following all the specifications of each & individual component.