Types of Garments Pattern Making Methods in The Apparel Industry

Garment construction is always convenient and time-saving if we follow certain principles of work. There are great benefits of paper pattern making. It proves to be time-saving. There are certain precautions to be maintained while making the paper pattern. The paper pattern should be made on a full-scale paper. In this article, we explain Different Types of Garments Pattern Making Methods in the Apparel Industry.

The smooth side of brown paper should be used for the pattern. The measurement booklet should be kept nearby. The drafting should be done in fine and clear lines only, the chalk or pencil to be used. Notches should be fixed at all the signs of designs, darts, pleats, balance marks, pockets, etc.

Paper patterns made in institutions etc. At the training level are made on the basis of basic measurements given. Paper patterns made at the tailoring shops are for individuals and these are made overseeing the body structure. People, who can’t do drafting, take the help of these patterns for layouts and cutting of the garment.

Definition of Pattern

A hard body copy of each component of the garments of the exact dimension of each component is called the pattern. The pattern includes seam allowance, trimming allowance, dirt, pleat, hem, ease allowance & any special design etc. Pattern design could be done manually or with the help of the computer.

Dart:

The purpose of a dart is to eliminate excessive fabric in a pattern so that it can be formed into a 3-dimensional shape to conform to the body shape.

Types of Garments Pattern Making:

There are two types of Garments Pattern Making Methods:

- Block pattern

- Garments pattern

Block pattern:

Block pattern is main pattern which is called basic block. This pattern is produced by the particular & standard body measurement of a body without decoration, design & style. It is made with average body measurements of children, young man & women.

Block pattern is produced in two ways or methods:

Flat method:

The individual components parts of garments particularly the body & sleeve are produced by drawing. It may be produced by manual or computer. Pattern can be done quickly in this system its use is less.

Modeling system:

The modeling system is the first & fundamental system of pattern-making. In this system, a block is made by a standard dummy which is called a toile & this toile puts on the dummy. Then it removes from the dummy & different parts of the garments are drawn on the hard paper. This system is the most exact or perfect but it takes more time.

Garments pattern

This pattern which is produced with the help of a block pattern or basic block is called a garments pattern. This pattern is placed on the board paper for producing copy with the pencil. Or marker. It is create by duplicating and modifying the final pattern to generate all the pattern pieces. It is usually made from card or plastic. Appropriate seam allowances are added. It becomes the master pattern for grading. Garment patterns have worked in many processes.

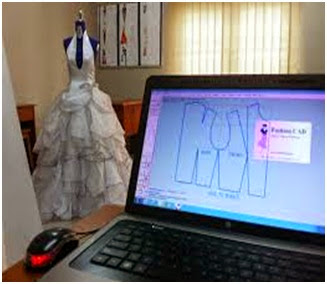

Computer –aided pattern design:

Computer –aided pattern design systems are similar to those used for fashion design, with the below given additions. Digitizing board and pattern scanner, either a drum or a flat bed plotter. In some cases, a flat bed pattern cutter for cutting patterns out of cardboard or plastic. Some potters also convert to pattern cutters.

The useful procedure is to digitize or scan a basic block pattern into computer memory and adapt it. Textile designs may also be superimposed onto patterns. The computer-aided pattern design is the innovation that is continually taking place. Programs that automatically generate bespoke patterns for men’s suits. Systems that improve the interface between the pattern designer and the computer.

Pattern grading:

Pattern for different size garments are derived from the master pattern using grading. Simple 2D grading changes height and girth measurements by a constant amount for each size. With 3D grading, as size changes, differential changes in pattern dimensions are required.

Pattern design and adaption are normally performed on a single size of pattern. Since people vary in size and stature, a range of patterns is required. A technique called grading is used to generate patterns for larger and smaller sizes from a standard size pattern.

Grading must be done accurately. Errors that occur when size is graded will produce similar errors in all other sizes which can result in time and resource wastage.

Grading system:

In 3D grading, grade points are allocated to key locations (zero points) on the pattern. Grade rules specify horizontal and vertical displacements for these points, as size is increased or decreased. These grade rules are compiled into a grade rule library. Once the library is created, it may be used for a similar pattern.

Marker making:

In lay planning, the pattern places are arranged for cutting. Markers provide plans of the arrangement and are drawn on the fabric or used as guides for cutting. The aim of lay planning and marker making is to ensure the most efficient use of the fabric.

The three methods of marker-making are as follows.

- Drawing pattern outlines onto the marker.

- Making directly onto the fabric

- Spray marking

Drawing pattern outlines onto the marker:

To draw pattern outlines onto the marker, a pencil, pen or chalk is used. It is the most convenient marker technique in which the fabric is invariably used on the fold.

Directly Making:

To mark directly onto the fabric, card patterns are laid onto the materials and chalked around using pipe-clay or wax. This method is the least accurate because of the difficulty in making on woolen or napped fabrics and unless the chalk is sharp one or two centimeters variations in pattern size may result.

Spray marking:

In spray marking, fine jets of paint are sprayed over the patterns that have been laid on the fabric, leaving an outline of the patterns when they are removed. This method is faster than chalking. However

- More fabric is required to allow gaps for paints.

- Paint can leak under the pattern edges.

- Pattern sizes grow as layers of point build up, and the machine must be cleaned every day.

Fabric spreading:

To allow several pieces to be cut from the same pattern, the fabric is spread to produce a lay of plies. The pieces can then be simultaneously cut out using the marker on top. Depending on their properties. Fabrics are spread differently.

Spreading is the process of stacking layers of fabric to allow simultaneous cutting. The fabric must be laid flat in single or multiple layers. The marker is placed on top of the spread. One edge of each of the fabric layers must be aligned. Tension-free devices, electronic edge sensors, and electric knives are used to ensure alignment requirements are met. Other materials that may be spread layers are-

- Interleaving tissue

- Ant fusion paper

Conclusion of pattern:

Pattern making is a highly skilled technique which calls for technical ability, and a sensitivity to interpret a design with a practical understanding of garment construction. For successful dress designing patternmaking forms the fundamental step. This function connects design to production by producing paper templates for all components such as cloth, hemming, fusible, etc. which have to be cut to complete a specific garment. So pattern making is too necessary for fabric measurement. It is an important part of garments. That’s all on the Types of Garments Pattern Making Methods.

- You may love to read: Pattern Grading Methods in the Apparel industry

- Responsibilities of CAD Manager in Garments Industry

- Comparison Between CAD Marker Making and Manual Marker Making