Medical textiles are special clothes or things that help when someone is hurt or sick. It’s a special fabric that helps keep us clean and healthy because it’s made just for our bodies. Different jobs need different fabrics, like keeping things safe, soaking up stuff, and stopping germs. In this article, I discussed different types of Medical Textiles, Applications of the Medical Textile, and Different Types of Materials Used in Medical Textiles.

Medical Textiles for doctors and nurses need to be strong, flexible, and breathe well. Additionally, they should have environmentally friendly production, be reusable, and be suitable for laundering/sterilization. Furthermore, they also need to be super clean and follow safety rules during the cleaning process.

Medical Textile Market

Medical Textile market was worth a lot, like 23 billion dollars, and might grow to 34 billion dollars by 2032. Additionally, in 2022, most of the specialized fabrics employed by medical professionals were non-woven (66%). Furthermore, elastic medical textiles are experiencing a growth rate of 3.6%. Asia held the largest share of specialized fabrics in 2022 (31%), and Europe is anticipated to grow by 4.5% from 2023 to 2032.

More people caring about health, surgeries, and implants make medical textiles more popular. Older people, healthcare investments, and efficient production also help the market grow. Better technology, different materials, and cost-cutting efforts make medical-grade textiles look promising.

The nonwoven segment is predicted to dominate the medical textile market, driven by increased demand during the pandemic, especially for face masks and gowns. Additionally, the knitted medical textiles segment is expected to thrive, fueled by rising demand for applications like cell scaffolds and artificial blood vessels.

The healthcare and hygiene products segment dominates the medical textiles market, with face masks, medical bags, bed sheets, and other items driving demand. As developing countries invest in healthcare facilities, the demand for medical textiles is expected to rise. Ongoing research in hi-tech medical textiles and the popularity of knitting technology further support market expansion. Types of Medical textiles, materials used in the Medical textiles, and applications are described below.

Different Types of Materials Used in Medical Textiles

All types of material are used Medical tex in the following:

1. Fibers

Natural fibers, like cotton, are short and called staple fibers. Synthetic fibers can be long filaments or cut into short lengths for various medical uses. They can be arranged neatly, randomly, or in soft masses for different applications, such as filters, non-woven fabrics, or medical implants.

2. Yarn

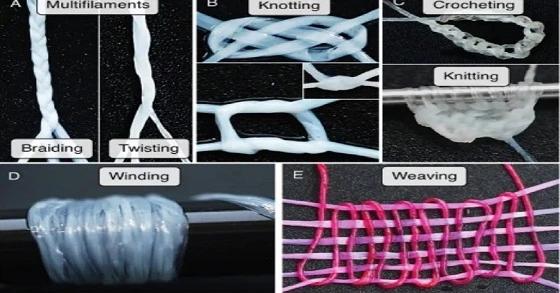

Yarn can be continuous filaments or staple fibers. Continuous filaments are twisted into multi-filament yarns. Staple fibers are carded, spun directly for a soft yarn, or combed for a firm yarn. Yarns can be twisted together for evenness and strength, creating two-fold or threefold yarns. Yarn is also classified by manufacturing method and linear density, measured in tex.

3. Woven Fabric

Woven fabrics, widely used in hospitals for bedding and clothing, have yarns interlaced at right angles. The fabric’s flexibility increases diagonally. Traditional woven fabrics like plain weave or 2×2 twill meet clothing and bed linen requirements. 3D woven fabrics have diverse applications in healthcare.

4. Knitted Fabric

Weft-knitted fabrics have horizontally interlinked loops, providing notable extensibility. Despite this, weft-knitted fabrics provide high compression and support, making them suitable for medical applications like hernia treatment. They are also used as scaffolds for tissue regeneration due to their positive effects on cell growth.

5. Nonwoven Fabric

Non-woven fabrics are efficiently produced without traditional yarns. Non-woven find extensive use in healthcare, including PPE and technical fields like dressings and filters. Environmental concerns lead to a shift toward semi-durable or recyclable non-woven items, challenging the disposable trend in medical textiles.

6. Braided Fabric

Braids, woven structures of interlaced threads, offer extensibility and varied applications. Tubular braids for implants emphasize packing tightness and resistance to kinking. Braided medical textiles include sutures and stents, with materials like polymeric and metal wires, as well as antibacterial-coated options.

7. Finishes

Textile finishing is important for defining or adjusting fabric properties, including the removal of impurities. Techniques like surface application, modification, and coating, along with heat treatment, enhance fabric properties. So, using these methods can make the fabric antimicrobial or antiviral, suitable for medical textiles.

Different Types of Medical Textile

1. Implantable Medical Textiles

An implantable medical textile is placed inside the body for medical purposes. Examples include sutures, vascular grafts, and resorbable polymer structures. Implantable medical textiles must match the biomechanical properties of body tissues, be biocompatible, and corrosion-resistant.

2. Non-implantable Medical Textiles

Non-implantable medical textiles comprise dressings, pressure garments, braces, splints, and trusses for diverse functions. Non-implantable devices, while not meeting the strict implant definition, can be invasive and require biocompatibility testing. Test rules should match the first plan and study of potential problems.

3. Medical Textiles as PPE and healthcare hygiene

Medical textiles for healthcare hygiene and PPE include disinfectant products, bed linen, protective wear, and more. They are used in various healthcare settings, from operating theaters to clinics. These textiles cover a broad range, including items like linen, orthotic devices, diapers, wipes, air filtration devices, and PPE such as surgical gowns and masks.

4. Extracorporeal devices

New technologies help organs, but we still need improvement. Some issues with circuits can cause problems like inflammation and blood clotting, which can harm patients. Creating a wearable kidney involves using nano-porous adsorbents for toxin removal, biocompatible polyester, and viscose rayon filtration. The artificial pancreas enhances glucose control through a closed-loop system, reducing hypoglycemia and improving diabetes self-care.

5. Medical Smart Textile

Smart textiles are becoming important in many areas, improving daily life and healthcare. Smart textiles can react to their surroundings and get energy from different sources, with the basic ability to sense the environment. They face challenges like data security.

Applications of Medical Textile

- Sutures: In surgery, stitches (sutures) help close wounds and aid healing. The best type of stitches depends on factors like the tissue, surgery type, and where they’re used.

- Stents, Valves, and Vascular grafts: The vascular system serves as a non-thrombogenic conduit for blood flow, regulating blood flow, pressure, and delivery to tissues. It comprises arteries, veins, and capillaries, each with unique structures. Grafts and stents, especially those made from nanofibers, offer advantages, with designs affecting performance. Heart valves, often replaced due to disease, are explored for textile-based solutions, like polyester and polyethylene terephthalate, addressing limitations and incorporating textiles in tissue-engineered valves for better functionality.

- Wound dressings: Wound dressings don’t directly heal wounds, but a well-chosen dressing can prevent harm, promote healing, and create an optimal environment. Wounds, based on their nature, require different treatments. Dressings are passive, interactive, or bioactive, each serving specific functions and reflecting advancements in wound healing science.

- Pressure Garments: Pressure garments are used in medicine for various purposes, such as preventing venous thromboembolism, treating burns, and managing fractures. However, these garments must exert pressure comfortably, be non-irritant, breathable, water-permeable, and exhibit favorable thermal behavior. Additionally, the ability to launder and reuse the garments is considered advantageous.

- Pads, Hospital bedsheets, Pillows: A standard hospital bed linen sheet can withstand thermal disinfection at 71°C. Disposable incontinence under pads, similikepers, can protect mattresses and furniture, and they may be reusable if the central layer has superabsorbent fibers. Wipeable pillows with flame-retardant polypropylene non-woven fabric covers are convenient for ease of care.

- Surgical Aprons, Hats, and gowns: Surgical gowns serve as a protective barrier to reduce surgical site infection and prevent contamination between the surgical team and the patient. They control the shedding of skin flakes and bacteria from the user and prevent direct microbial transmission. Additionally, surgical gowns must provide comfort for the surgical team, especially during longer operations

Conclusion

Medical textile is a revolution of Modern sciences. Different types of Medical textiles have different applications according to human needs. Woven, knit, Nonwoven, and braid; all 4 types of fabric are used in Medical textiles. So the very important part is technical textiles. Day by day more developments are coming with many innovations in this sector. This is playing a big role in our medical sector. That’s all in this article about different types of Medical Textiles, Applications of the Medical Textiles, and Different Types of Materials Used in Medical Textiles.

- You may love to read: 8 Key Applications of Nonwoven Fabric

- Nonwoven Fabric Manufacturing Process: 3 Steps

- Classification of Medical Textile

- Recent Developments in Medical Textiles

- Top 20 Medical Textile Manufacturers /Companies in the World

- Applications of Nonwoven Fabric in Medical Textiles